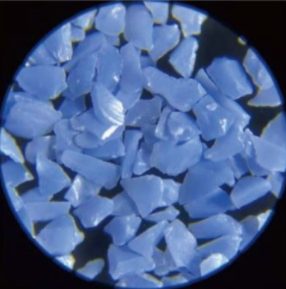

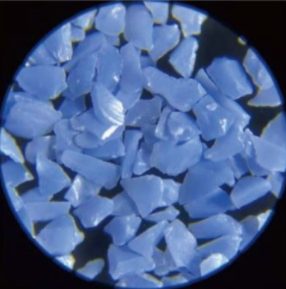

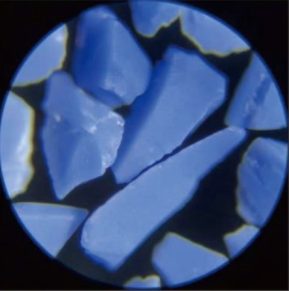

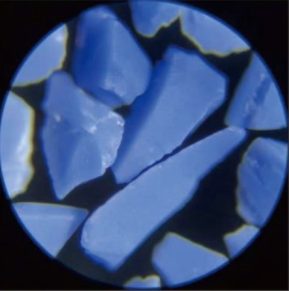

Blue Ceramic Alumina - SG-schuurmiddelen

SG Abrasives is a cutting-edge abrasive material that revolutionizes the grinding and polishing industry. Known for its exceptional durability and superior performance, SG Abrasives is a top choice for various industrial applications.

- Fast cutting speed

- Lang leven

- Fast cold cutting, no burns

Invoering

![]()

![]()

Fysieke eigenschappen

| Kleur | Blue | |||

| Vickers Hardness | 1920-2100 | |||

| Ware dichtheid | 3.90g/cm3 | |||

| Crystal size | 100nm~500nm | |||

| Grit Number | F16~F220 , P24~P220 | |||

| Sepcial Grit number | TB24+~TB220+ | |||

| High LDP grit | HF16~HF240, HP24~HP240 | |||

| Micropoeder | JIS #240~#10000 | |||

| F230~F2000 | ||||

| P240~P3000 | ||||

Loose Pack Density(LDP)Limits:(Macro Sizes)

| Korrel | Bulkdichtheid (g/cm3) | High LDP | |||

| TB | P | F | HF | HP | |

| 16# | – | – | 1.85-1.97 | >1.97 | – |

| 20# | – | – | 1.85-1.97 | >1.97 | – |

| 24# | 1.75-1.85 | 1.80-1.92 | 1.83-1.95 | >1.95 | >1.92 |

| 30# | 1.75-1.85 | 1.79-1.90 | 1.80-1.92 | >1.92 | >1.90 |

| 36# | 1.75-1.85 | 1.78-1.88 | 1.79-1.91 | >1.91 | >1.88 |

| 40# | 1.72-1.82 | 1.76-1.86 | – | – | >1.86 |

| 46# | – | – | 1.77-1.89 | >1.89 | – |

| 50# | 1.70-1.80 | 1.75-1.85 | – | – | >1.85 |

| 54# | – | – | 1.73-1.85 | >1.85 | – |

| 60# | 1.68-1.78 | 1.71-1.82 | 1.71-1.83 | >1.83 | >1.82 |

| 70# | – | – | 1.67-1.79 | >1.79 | – |

| 80# | 1.66-1.76 | 1.68-1.80 | 1.68-1.80 | >1.80 | >1.80 |

| 90# | – | – | 1.67-1.79 | >1.79 | – |

| 100# | 1.66-1.76 | 1.66-1.78 | 1.67-1.79 | >1.79 | >1.78 |

| 120# | 1.66-1.76 | 1.66-1.78 | 1.67-1.79 | >1.79 | >1.78 |

| 150# | 1.66-1.76 | 1.66-1.78 | 1.67-1.79 | >1.79 | >1.78 |

| 180# | 1.66-1.76 | 1.66-1.78 | 1.67-1.79 | >1.79 | >1.78 |

| 220# | 1.66-1.76 | 1.66-1.78 | 1.67-1.79 | >1.79 | >1.78 |

Toepassingen

| P | Ideal for coated abrasives. |

| F | Ideal for bonded abrasives. Resin bonded grinding wheel and Vitrified bonded grinding wheel. |

| TB | Ideal for coated abrasives,Lower LDP than P grit larger grain size than P grit. |

| Used with conventional abrasives of the same grit number,Conventional abrasives are used as supporting parts at the bottom of coated abrasives. | |

| Ceramic abrasives grains is the main grinding force,on the top layer. | |

| HF | LDP higher than normal F grit, With higher toughness. It has the highest toughness of the ceramic abrasives. |

| Used with diamond abrasive, in resin grinding wheel, improve sharpness and life. | |

| HP | LDP higher than normal P grit. Ideal for heavy duty coated abrasives. |

| RF | Surface treated F grit. Ideal for cut-off discs and abrasive discs. |

| M | Micro powder particle size range: Japanese standard JIS240 – JIS8000; National standard F230~F1500;200/230~W3.5. |

| TG | High material removal-rate applications. |

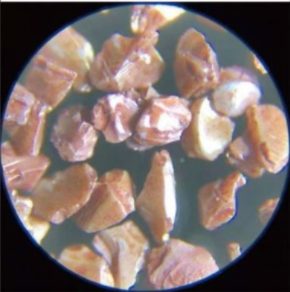

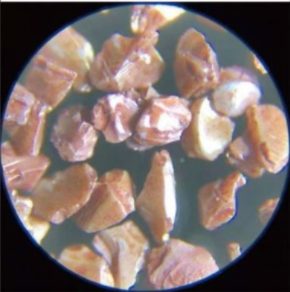

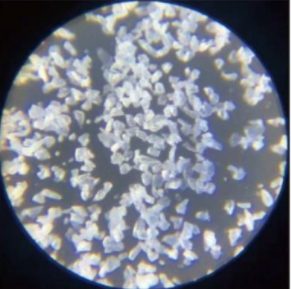

Zwart siliciumcarbide

Zwart siliciumcarbide is een veelgebruikt schuurmiddel, met uitstekende slijtvastheid, hoge hardheid, hoge dichtheid, lage onzuiverheden en andere voordelen:, vaak gebruikt bij zandstralen slijpen;, polijsten, gratis slijpen, verschillende schuurmiddelen maken, enz.

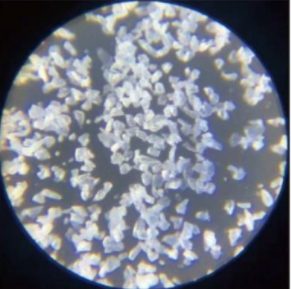

Groen Siliciumcarbide

Groen siliciumcarbide wordt gemaakt van kwartszand en petroleumcokes, geraffineerd in een weerstandsoven, vanwege de relatief stabiele chemische eigenschappen, hoge thermische geleidbaarheid, lage thermische uitzettingscoëfficiënt, en goede slijtvastheid:.

Neem contact met ons op

Vraag een offerte aan

E-mailadres

sales@superior-abrasives.com

+86-18638638803

Adres

No.68 Zhengtong Road, Zhengzhou, Henan, China